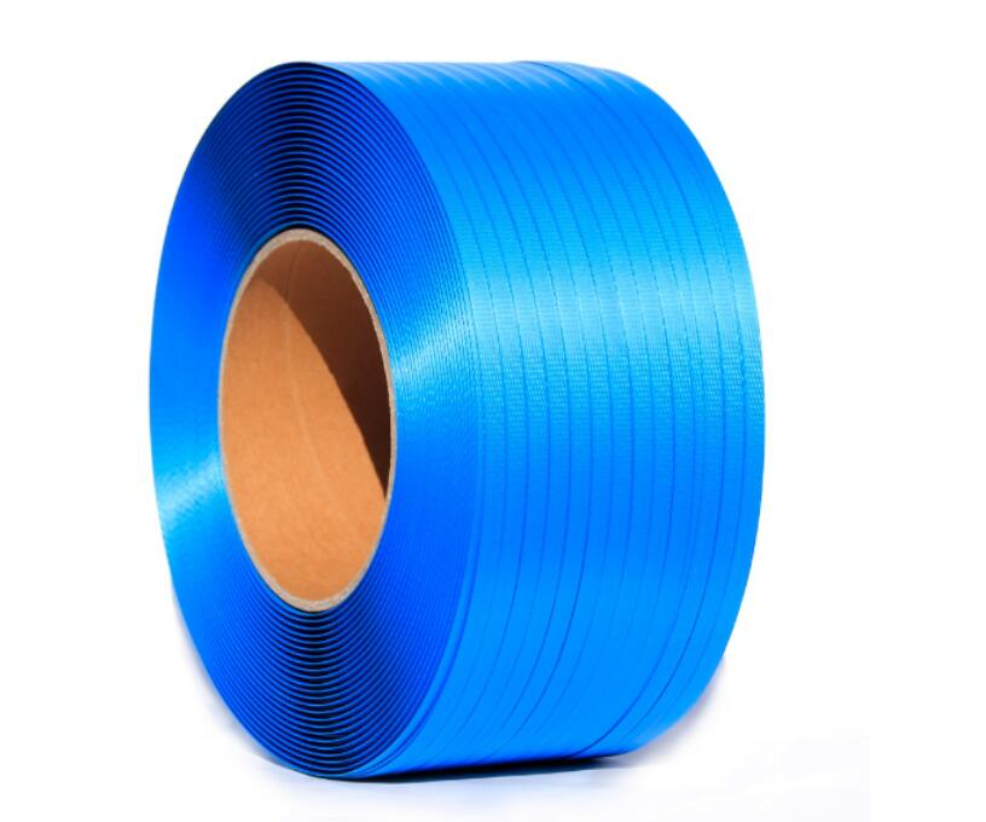

A PP strapping band (Polypropylene strapping band) is a type of packaging material made from polypropylene plastic, widely used for securing, bundling, and stabilizing products during transportation and storage. It is known for being lightweight, flexible, and economical, which makes it popular for applications across industries like shipping, logistics, and manufacturing.

Key Characteristics of PP Strapping Bands:

- Material: Made from polypropylene, a durable and recyclable plastic, PP strapping bands are resistant to moisture, chemical exposure, and most weather conditions.

- Strength and Flexibility: PP strapping is strong enough to secure loads but also provides flexibility, which reduces the risk of damaging items with sharp or irregular edges.

- Cost-Effective: Polypropylene is an affordable material, so PP strapping is often chosen as a cost-effective alternative to other strapping options like steel or polyester (PET) strapping.

- Variety of Sizes and Thicknesses: PP strapping is available in various widths, thicknesses, and tensile strengths to suit different load requirements.

- Ease of Use: It can be applied manually or with automatic or semi-automatic strapping machines, making it convenient for both small and large packaging operations.

Common Applications:

- Box Strapping: Used to secure boxes in warehouses or during shipping.

- Pallet Strapping: Helps stabilize goods on pallets, preventing movement during transportation.

- Bundling Items: Useful for bundling irregularly shaped items or products with sharp edges without damaging the items.

Comparison with Other Strapping Materials:

- Steel Strapping: Offers higher tensile strength and is preferred for extremely heavy loads, but it’s less flexible and more costly.

- PET Strapping: Provides higher strength than PP and is more suitable for heavier loads or long-term outdoor storage since it resists UV damage better.

PP strapping bands are ideal for lightweight to medium-weight packaging needs, providing a secure, economical solution that ensures safe product transportation.

Related Searches: PP strapping bands, polypropylene strapping, cost-effective strapping solutions, packaging and logistics strapping.